Keep ahead of the threat

Stay up to date with the latest mycotoxin information by signing up to our newsletter

Mycotoxin control: A view from the field

Author: Martin Minchin, Mycotoxin Management Marketing Manager, Alltech Mycotoxin Management

Working with Alltech’s European Technical Support team, Dr. Hazel Rooney and Per Laustsen spend a lot of time supporting pig producers in ensuring they are optimizing the health and performance of their herds. In such dynamic environments, where even the slightest change in feed quality can have significant repercussions on animal productivity, effective mycotoxin control is one of the key areas that Hazel and Per are focused on in their daily interactions with pig producers.

What is the mycotoxin risk in pig feeds?

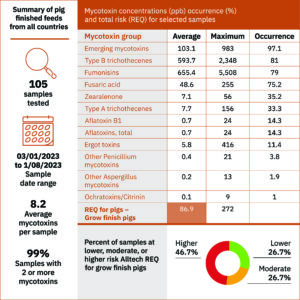

A key first step in managing the mycotoxin challenge is identifying the contamination profiles that exist in either raw materials or finished feeds. Between Alltech® RAPIREAD™ and Alltech 37+®, over 15,000 samples are being assessed each year across the Alltech network. The presence of multiple mycotoxins is the norm rather than the exception; year on year, over 95% of samples submitted to the Alltech 37+ labs contain two or more mycotoxins. Looking at finished feeds for pigs specifically, samples submitted in the past six months have contained an average of 8.2 mycotoxins per sample. When Alltech’s Risk Equivalent Quantity (REQ) metric is applied to these samples, almost 50% are categorized as presenting a higher level of mycotoxin risk to grow-finish pigs. REQ is a unique metric that Alltech have developed to measure the cumulative risk of mycotoxin in raw materials or finished feeds.

Figure 1. The mycotoxin risk profile in global finished feeds destined for consumption by grow-finish pigs.

Detecting dietary intake of mycotoxins

Reflecting on what is driving that risk, Dr. Rooney highlighted the presence of Fusarium mycotoxins such as deoxynivalenol (DON), T2-HT2, fumonisins and zearalenone. Pigs are one of the most sensitive species to these mycotoxin types, and the impacts of ingestion can manifest in a range of different ways. Signs of DON contamination typically include feed refusal or a drop in feed intake. In more acute cases, dietary intake of DON leads to vomiting. Zearalenone is one of the mycotoxins known to cause diseases related to infertility in gilts and sows, with breeding animals exposed to zearalenone exhibiting vaginal and rectal prolapses and reduced pregnancy rates. Aflatoxin ingestion is also attributed to reproductive issues, including increased embryonic mortality, abortions, and a reduction in the number of piglets born alive.

From a Danish perspective, Per noted the subtle signs that can indicate otherwise hidden mycotoxin issues in a pig herd. As cases of acute mycotoxicosis become less common, the topic of low-risk or chronic exposure is gaining more interest in the mycotoxin category worldwide. When assessing pig health and performance, Per likes to look at areas like small changes in feed conversion efficiency (FCE), compromised growth rates, or piglet diarrhea. Over a prolonged period, these less severe issues can still put a large dent in farm productivity and profitability.

Straw: The hidden danger?

Adhering to enhanced welfare regulations, pig producers in Europe are using greater amounts of straw as a bedding material in their barns. Because it is not typically regarded as a mycotoxin contaminant of concern in pig production, and because it is not included in feed formulas like grains or other materials are, straw is rarely tested for mycotoxin presence. However, the Danish team took a proactive approach to this and began testing straw used in pig bedding. Most of these tests detected higher risk, with DON being the major toxin of concern. These DON levels are likely resulting from straw that is left on the ground between harvest and baling, or stored outdoors over winter.

After seeing the mycotoxin exposure that straw can cause, many pig producers are working to assess mycotoxin levels in the straw on a more regular basis. The number of straw samples submitted from Denmark to the Alltech 37+ lab continues to increase year on year. Once the straw is tested and mycotoxin levels are known, the highest quality straw is then typically reserved for breeding sows, while mitigation strategies can also be put in place.

Top tips for mycotoxin control

Increasingly, pig producers are also seeking to prevent mycotoxin challenges by improving storage practices. Although Dr. Rooney acknowledges that it is pretty much impossible to eliminate the threat of mycotoxins entirely, she does offer some key advice—based on both her technical knowledge and her daily on-farm experience—on how to achieve the most effective mycotoxin control:

- Clean regularly: To prevent old feed accumulating, feed bin interiors should be cleaned out with a pressure washer and left to dry completely before they are refilled when possible.

- Empty bins: Run bins empty before refilling them with new deliveries or at least allow bins to run empty 2-3 times per year.

- Use a mold inhibitor: Every six months, run bins empty and treat them with a mold inhibitor.

- Monitor storage conditions: Avoid warm or damp storage conditions; keeping the moisture low in storage environments is vital for controlling the level of mold and subsequent mycotoxin development.

- Maintain storage facilities: Keep these facilities in good condition to prevent leaks and minimize access by rodents, birds and insects.

Adding to this list, when it comes to mycotoxin control, Per operates on the mantra of test, test, test. When armed with the most up-to-date insights on mycotoxin contamination, feed and livestock producers are empowered to make the most informed feed management decisions.

Alltech’s harvest analysis program

Each year, Alltech conducts a harvest analysis program across the key grain-growing regions of Europe and North America. As mycotoxin risks change with each new crop year, these programs are vital in helping feed and livestock producers to understand the latest trends in mycotoxin contamination. Over the next few months, thousands of samples of the most widely used feed ingredients, such as corn, wheat and barley, will be assessed across our Alltech 37+ lab network and via our partnership with SGS, a respected leader in mycotoxin testing for the global grain trade.

As these results become available, we will be sharing them across a range of different media channels and in-person workshops. Stay tuned for further updates.

If you are a pig producer and would like to know more about implementing a strong mycotoxin control program, please visit knowmycotoxins.com or contact your local Alltech representative.